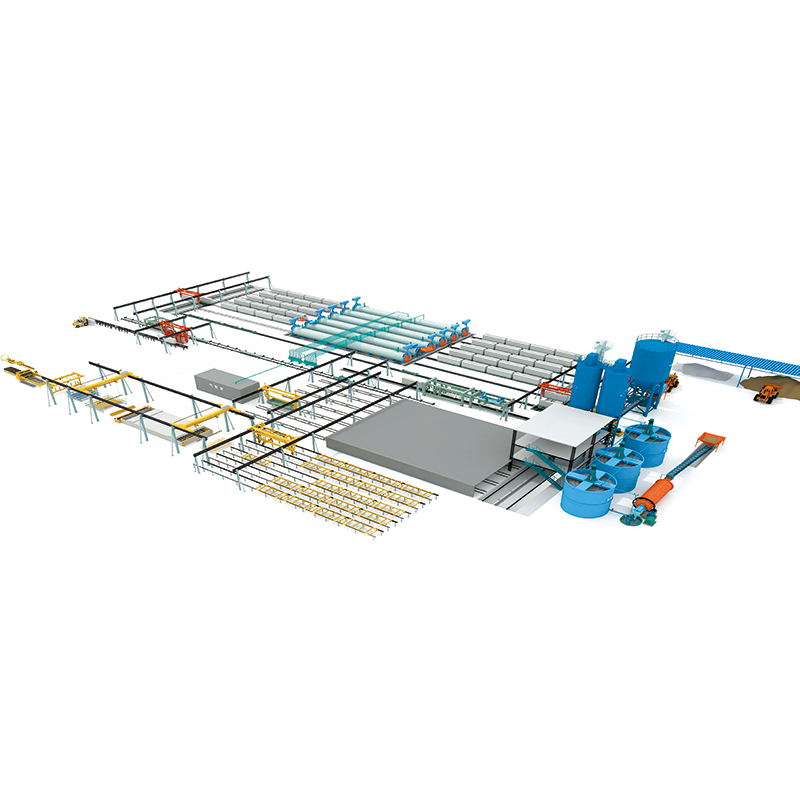

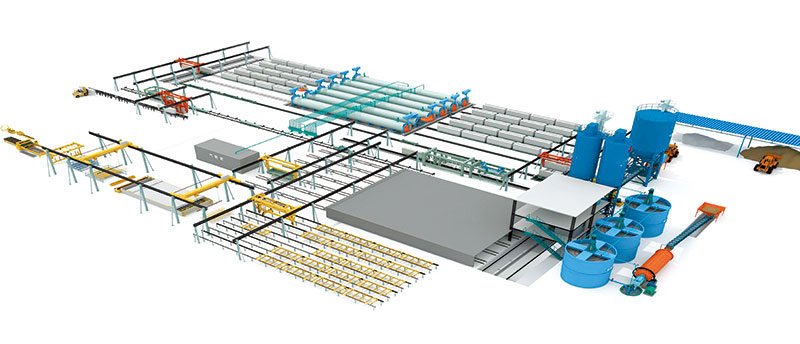

The autoclaved aerated concrete block equipment consists of seven parts, namely: raw material pretreatment equipment, raw material metering equipment, material mixing and pouring equipment, fully automatic flipping and cutting machine, autoclaves, boilers, and other auxiliary equipment.

1、 Raw material pretreatment equipment. The raw materials will undergo preliminary processing for subsequent production.

1. Crusher: used to crush block materials such as gypsum, quicklime, etc., and enter the next process. This is the main equipment of autoclaved aerated concrete block equipment.

2. Ball mill: After crushing, quicklime and gypsum must be ground for better reaction. This is a specialized equipment for the production line of autoclaved aerated concrete block equipment.

2、 Raw material measuring equipment. The raw material measuring equipment for autoclaved aerated concrete block equipment generally adopts a computer-controlled automatic measuring system.

3、 Material mixing and pouring equipment. This equipment is mainly a mixer, which is a mixing device and also a slurry pouring device that thoroughly mixes raw materials.

4、 Flip cutting unit. Its main function is to form a large volume blank after the autoclaved aerated block is poured and aerated. To achieve the required product size, a cutting machine must be used for cutting.

5、 Autoclave. Autoclave is a device used for the hydration reaction of silicate products to obtain their physical and mechanical properties. Throughout the entire production process, the autoclave is an important component related to safety production and energy utilization.

6、 Boiler. A boiler is a heating eq

The autoclaved aerated concrete block equipment consists of seven parts, namely: raw material pretreatment equipment, raw material metering equipment, material mixing and pouring equipment, fully automatic flipping and cutting machine, autoclaves, boilers, and other auxiliary equipment.1、 Raw mater

Interested in the AAC Production Line Fill out the form and our specialists will contact you.